The real improvements in productivity and competitiveness in a company are those which achieve an increase in output with the same or fewer resources or the same output with fewer resources.

What is OEE?

OEE (Overall Equipment Effectiveness) is an indicator used to measure the efficiency of these resources. This indicator is always expressed as a percentage and indicates the use of the real productive capacity of industrial equipment and machinery. If its value is close to 100%, the optimal situation, the resources are being used to their fullest, whereas if its value is under 100%, the company’s productive capacity is not being fully exploited and, therefore, the situation can certainly be improved.

Therefore, this indicator not only shows an optimal use of resources, but also reveals the waste that occurs during the different processes and thus prevents production at the highest capacity.

It is also important to state that the OEE is applicable to any production process, as long as a standard has been set for it.

How is OEE calculated?

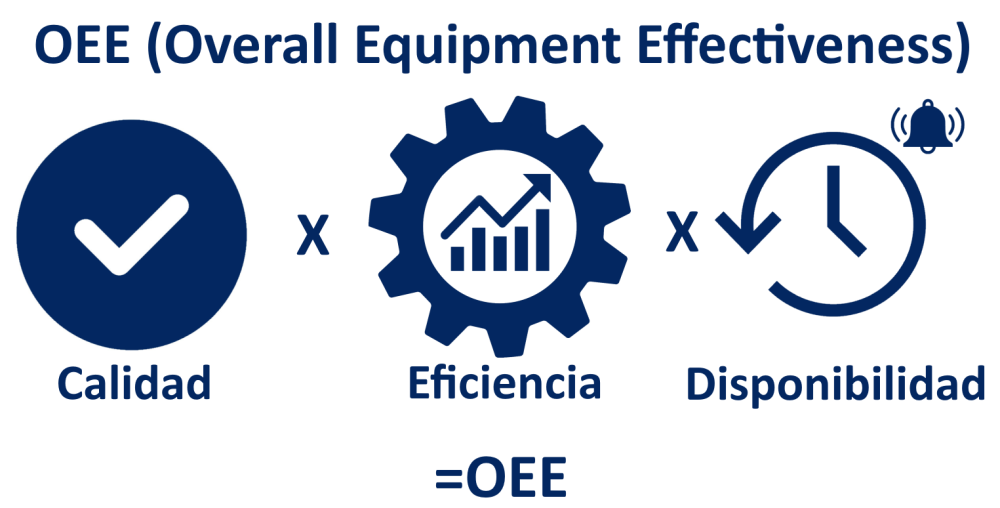

Three variables are multiplied to calculate OEE: quality, speed and availability.

- Quality: quality losses occur when not all parts are considered valid and, therefore, time and material resources have not been used in an optimal way. This refers to low-quality parts/elements that are rejected, need to be improved, etc.

- Performance: losses in speed or performance are caused by micro-stops, cycles without production or drops in output pace.

- Availability: availability is not at its optimum when time is lost due to technical stoppages, breakdowns, replacement of machinery or personnel, etc. and the scheduled time is not achieved for a variety of reasons.

As it is a multiplier of all three variables, if any of them is not at 100%, the OEE will not be at 100% either.

Most companies have an OEE of well under 100%. Therefore, they are wasting resources and are not exploiting their full potential.

How does APPRODUCTIVITY 4.0 help you to improve OEE?

Our APPRODUCTIVITY 4.0 software provides tools which can be used to set and document work and production standards (for different scenarios which can be simulated), to accurately calculate various indicators (KPIs), including OEE, to monitor the work progress, to detect deviations and to reschedule in real time.

Therefore, our software can mainly help you to improve OEE in three ways:

- Engineering (“static”). APPRODUCTIVITY 4.0 WORK ANALYSIS includes functionalities and tools that facilitate the definition of standards (work methods, execution times, workload balancing – static line balancing -, the improvement of set-up and changeover times – SMED (Single Minute Exchange of Dies) -, and the drafting and maintenance of work instructions, etc.).

- Production (“dynamic”): The Dynamic Line Balancing module (EQUDIN-MES) facilitates the identification of the gap between standard and reality. In other words, it offers the opportunity to detect early on deviations between forecast (standard) and reality and therefore offers the opportunity to reschedule in real time.

- Management: It also features a module (Competitiveness KPIs and Incentives Manager) that can be used to define KPIs (industrial management indicators, including OEE) and to manage variable remuneration and incentive systems. As mentioned above, it is important to establish the most appropriate indicators for each process in order to be able to monitor their performance and achievement. In addition, APPRODUCTIVITY 4.0 also makes it possible to calculate and manage incentive systems to reward employees who have contributed to the achievement of objectives or process savings.

If you would like to find out more, please contact us by filling out the form below. We will be happy to explain in greater detail how our software can help you improve your company’s OEE.